scrolldown

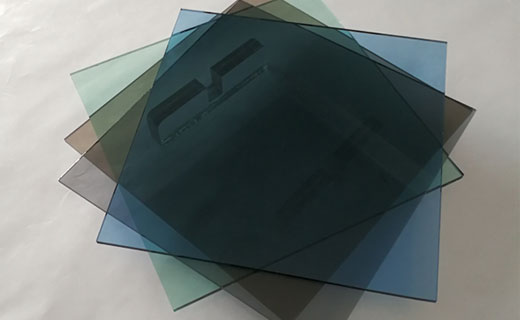

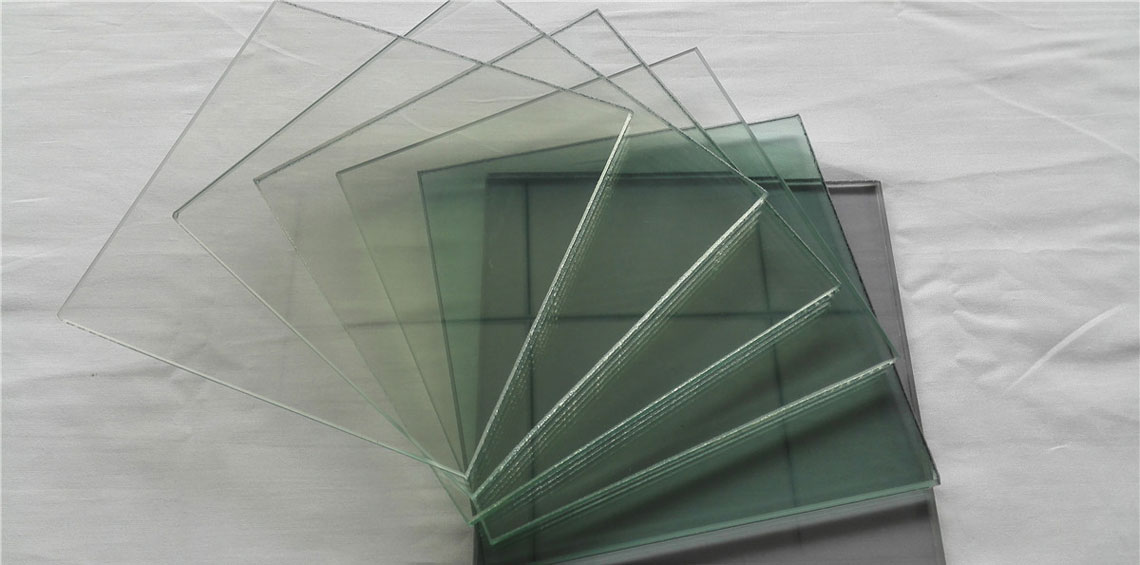

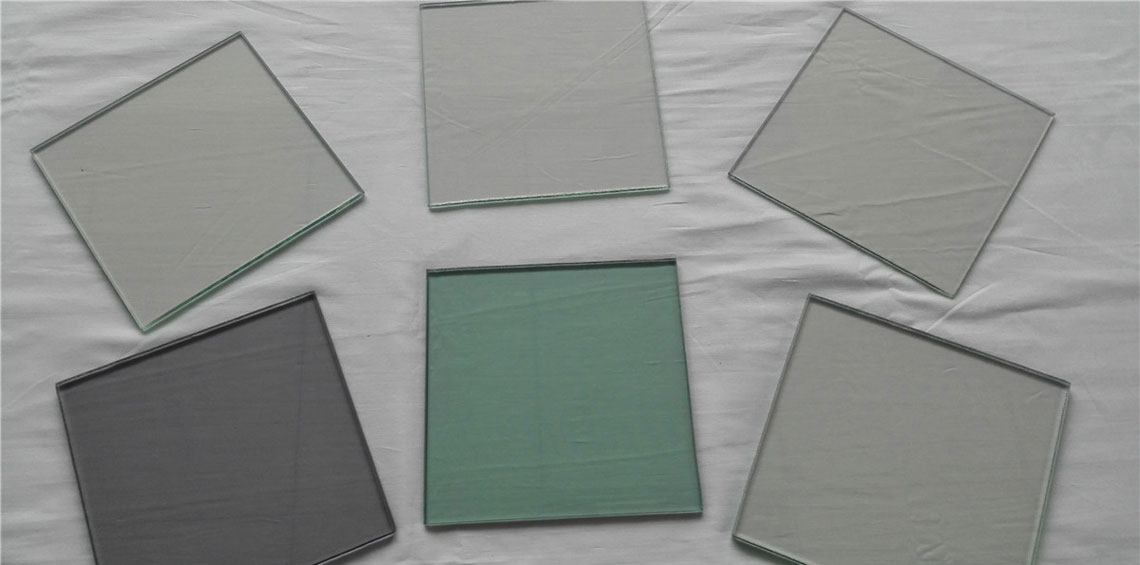

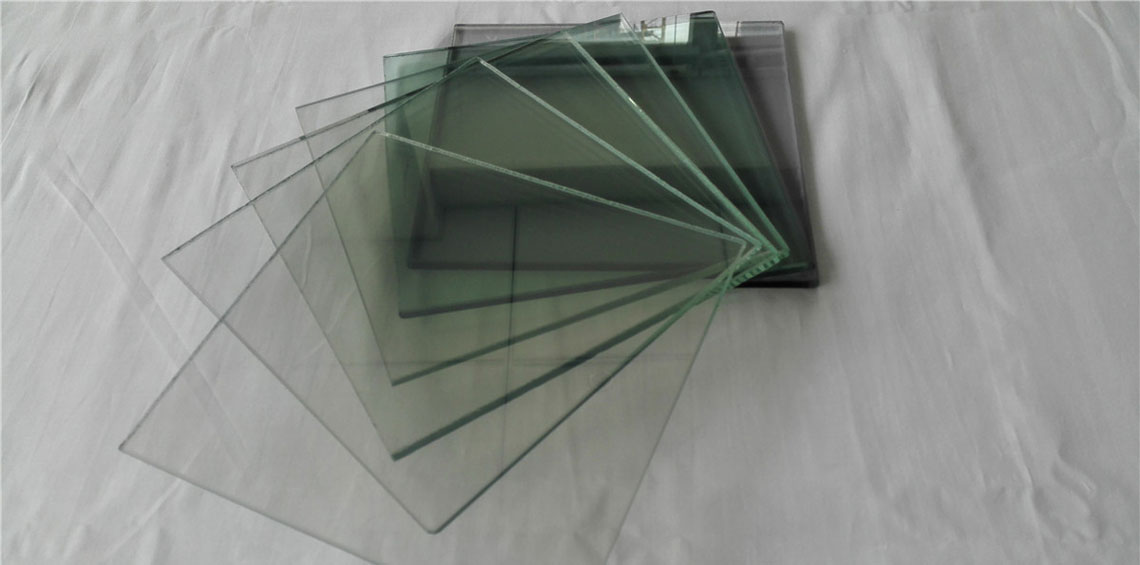

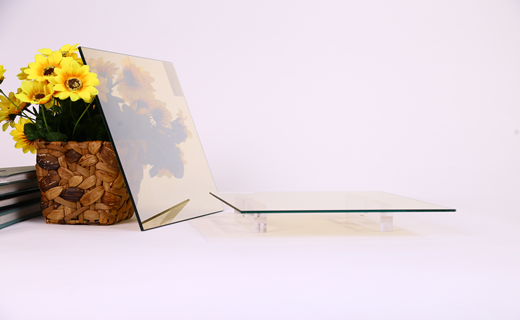

Coated Glass

Coated glass is coated with one or more layers of metal, alloy or metal compound film on the glass surface to change the optical properties of the glass or to meet certain requirements.

Product variety:

Thickness: 3.2, 4, 5, 6, 8mm.

-

Introduction

+Coated glass is coated with one or more layers of metal, alloy or metal compound film on the glass surface to change the optical properties of the glass or to meet certain requirements.

According to the different characteristics of the coated glass,it can be divided into the following categories: heat reflective glass, low-E glass (Low-E), conductive glass

Heat reflective is generally coated with one or more layers films of chrome, titanium, stainless steel or other chemical compound film which make the products colorful, appropriate transmittance for visible light, high reflectivity for infrared ray, high absorption rate for UV, so it’s also called as sun control glass, mainly used in architectural building and glass curtain wall.

Low-E glass (Low-E) is made of coating with multi-layer of 10-20 nm silver, copper or tin and other metals or its compounds film system by Vacuum magnetron sputtering method on the glass surface. The product with a higher transmission for visible light rate, a high reflectivity for the infrared and good thermal insulation properties which can make the glass emissivity from 0.84 down to 0.1 or less, radiation loss reduced by 90%. Low e glass is mainly used in construction and automotive, ship and other means of transportation tools, but are generally used by fabricating into insulated glass because of its poor film strength.

Conductive film glass (ITO) is made by coating indium tin oxide and other conductive film on the glass surface. It can be used for glass heating, defrosting, defogging and as a liquid crystal display screen as well.

There are many manufacture methods of coated glass, mainly including vacuum magnetron sputtering method, vacuum evaporation method, chemical vapor deposition method and sol-gel method. Magnetron sputtering coated glass uses magnetron sputtering technology to design and manufacture multi-layer complex film system. Its glass substrate can be plated in a variety of colors, the film corrosion resistance and wear resistance is better. Moreover this kind of glass product is manufactured and used for most currently.Varieties and quality of vacuum evaporation coating glass exist a certain gap when compared with magnetron sputtering coated glass and has been gradually replaced by the latter. Chemical vapor deposition method is to fill reaction gas in the float glass production line and make burning of the glass surface decomposition, evenly deposited on the glass surface to form coated glass. The method is characterized by less investment in equipment, easy to control, low product cost, good chemical stability, can be hot processing, is one of the most promising production methods. Sol-gel method to produce coated glass is simple and stable, and the shortcomings are that the product light transmission ratio is too high and the decoration is poor.

The most useful coated glass are heat reflective glass and low-e, it mainly use Vacuum magnetron sputtering method and Chemical vapor deposition method.

Glass type

Thickness: 3.2, 4, 5, 6, 8mm

Features:

1. Thermal insulation: It has the character of reflection of far infrared heat based on maximum visible light into the room, it could control the solar energy.

2. Energy saving: the insulated glass made of coated glass could interdict the heat transfer adequately, with different coated glass, it could make our room warm in winter and cool in summer, also reduce the air condition’s installed capacity and running energy consumption.

3. Sunshade: sole silver, double silver, or tri-silver made, high sunshade coefficient coated glass could be best minimum the transmittance of the sun's radiation, and make the room refreshing and pleasant.

4. Colorful: according to the different usage, we could coat different colored film, satisfy architect different pursue on the beauty of building.

5. Conductivity: By adding tin element to indium oxide coated on the glass surface, improve the conductivity, without affecting the glass transmittance case, the lowest resistivity of up to 10-5Ωcm order, with good electrical conductivity, it could be used glass’ heat, defrost, demist, LCD etc home appliance electronic industries.

6. One-way perspectivity: we could make high reflective one-way perspectivity glass by coating high reflective steel film to the different colored high quality glass sheet, or we use high reflective coated glass recombinate with other float glass sheet to make one-way perspectivity glass with impact resistance. It mainly used in inspection window of intensive care ward in hospital, police station or hearing room of prison.

Production Capacity:

Maximum specification: 2440*3300mm

Minimum specification: 1650*2134mm

Thickness: 3.2~8mm

Output: 21.9 million tons/ year

Orders out of above specifications are negotiable.

Technical and quality standards:

Complying with Europe standard: EN12150-2:2004;

Australia standard: AS/NZS 2208-1996;

United State standard: ANSI Z97.1-2004;

Chinese standard : ANSI Z97.1-2004

-

Certificates

+ -

Sales network

+Contact:David xu

Mobile:+86 13573200010

Tel:+86 0532-55711426

Fax: +86 0532-86880938

E-mail:sales@qdpioneerglass.com

http://www.qdpioneerglass.com/