scrolldown

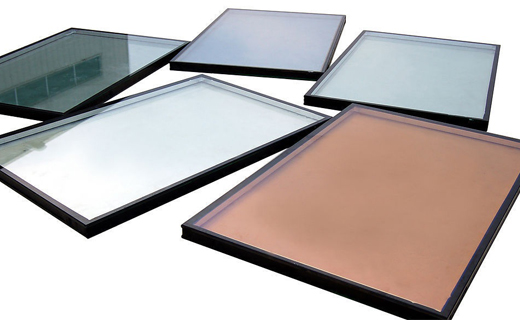

Insulating glass

Insulated glass is made of two or more pieces of glass that effectively supported and separated each other by a sealed yet framed dry air cavity. The cavity is sealed by a hollow aluminum frame (which filled with desiccant) or compound seal string, while

Product variety:

We can provide various insulating glass products in different shapes that meet different energy-saving requirement by using any flat glass(including float glass,coated solar control glass,low-e coated glass,colored glass,laminated glass,tempered glass,hot

-

Introduction

+Insulated glass is made of two or more pieces of glass that effectively supported and separated each other by a sealed yet framed dry air cavity. The cavity is sealed by a hollow aluminum frame (which filled with desiccant) or compound seal string, while filled with dry air or inert gas into it, then to sealed by butyle, poly-sulfide sealant or structural sealant to keep the whole glass product’s leakproofness. According to the number of hollow cavity insulated glass can be divided into single-layer insulated glass, double-layer insulated glass and multi-layer insulated glass. Single-layer insulated glass is composed of two flat glass and a hollow cavity; Multi -layer insulated glass is composed by two or more hollow cavities. The more the cavity, the better the insulation and sound insulation, the most widely used is a double silver coated single layer insulated glass, double insulated glass and triple layer insulated glass.

The products can be widely used in glass curtain walls,doors and windows of industrial and high-end buildings, the window and door perspective parts of trains,ships,aircrafts and instruments,and the places that require thermal insulation and temperature control and dew control,such as: government project ,office ,hotel ,library home appliance ,cold storage room and other observation doors and Windows, Effective sound insulation and prevent heat transfer.

Insulating Glass Categories

We can provide various insulating glass products in different shapes that meet different energy-saving requirement by using any flat glass(including float glass,coated solar control glass,low-e coated glass,colored glass,laminated glass,tempered glass,hot bent glass or self-cleaning glass) according to the requirements of customers,such as:building curtain wall、window and door glass、clamping glass with safety decoration function、blind insulating glass、coating low-e insulating glass、laminated structural insulating glass、arcuate insulating glass、automobile insulating glass、instrument peephole insulating glass and home appliances heat insulation insulation board and so on.

Characteristics:

1.The performance of the sound insulation:to meet people's demand for lighting, viewing, decoration, environmental protection, and to make a more comfortable human existence environment and prevent noise pollution at the same time.

2、Thermal insulation performance: In summer, can effectively block outdoor heat enter indoor; In winter, prevent indoor heat loss to outdoor, reduce air conditioning and other heating bills, save energy consumption, See table 2-2.

3、Temperature resistance、heat resistance、moisture resistance、cold resistance, anti-frosting、anti-sweat.

4、Light performance of engineering construction:On the basis of meet the requirements of building energy efficiency design, the insulating glass is much lighter than other glass or building materials of the same thickness, convenient construction for personnel operation , It can also effectively reduce the load capacity of the building structure itself .

5、Self-cleaning property:The insulating glass made from self-clean glass also has the properties of water-loving anti-mildew, deodorant degradation of organic pollutants and the decomposition of harmful substances、purifying air.

Production Capacity:

Maximum specification: 3600mm×18000mm

Minimum specification: 245mm×180mm

Width of aluminum frame: 4A、6A、8A、9A、12A、15A、16A、20A

Thickness: Any custom

Output: 750,000㎡/ year

Orders out of these specifications are negotiable.

Executive Technical and Quality Standards

European standard:EN50-2:2004; Australian standard AS/NZS 2208-1996;

American ANSI Z97.1-2004; Complying with Chinese GB15763.2-2005;

Transmittance and Energy Conservation of Insulating Glass

Table 2-1 Transmittance of different types of insulating glass 121

Table 2-2 Energy-saving thermal insulation coefficients of various types of insulating glassGlass structure

Transmittance /%

Single glass

90 Common two-layer insulating glass

84 Three-layer insulating glass

72 Low-e insulating glass

70-80 Colored thermal reflective insulating glass

38-60

Note: A is the air; Kr is the krypton gas.Structure of insulating glass

Sealing materials

Window frame materials

U value/[W/(㎡.K)]

5mm clear glass+9A+5mm clear glass

Aluminium frame, polysulfide sealant

PVC

2.36 5mm clear glass+9A+5mm clear glass

Swiggle strip

PVC

2.29 5mm clear glass+9A+5mm LOW-E

Aluminium frame, polysulfide sealant

PVC

1.82 5mm clear glass+9A+5mm LOW-E

Swiggle strip PVC

1.72 5mm clear glass+9A+5mm clear glass+9A+5mm clear glass

Aluminium frame, polysulfide sealant

PVC

2.17 5mm clear glass+9A+5mm clear glass+9A+5mm clear glass

Swiggle strip

PVC

2.02 5mm clear glass+9A+5mmLOW-E+5mm clear glass

Aluminium frame, polysulfide sealant

PVC

1.59 5mm clear glass+9A+5mmLOW-E+5mm clear glass

Swiggle strip

PVC

1.47 5mm clear glass+9Kr+5mm clear glass

Aluminium frame, polysulfide sealant

PVC

1.28 5mm clear glass+9Kr+5mm clear glass

Swiggle strip

PVC

1.18 5mm clear glass+9Kr+5mm clear glass

Aluminium frame, polysulfide sealant

Aluminium alloy without thermal partition

1.72 5mm clear glass+9Kr+5mm clear glass

Swiggle strip

Aluminium alloy without thermal partition

1.66

Acoustic Insulation of Insulating Glass

The loudness of sound is measured in decibels (dB). The noise of 60 decibels (dB) will make people uncomfortable; the noise of 80 decibels (dB) will irritate people; the noise of 90 decibels (dB) may cause hearing impairment and the noise of 120 decibels (dB) is out of the normal range of the senses. Standard of environmental noise of urban area is shown in Table 2-3.

Table 2-3 GB 3096-93 standard of environmental noise of urban area (in dB)

Zones

Daytime

Night

Special silent zones (sanatorium, villa area, etc.)

50 40 Residential, culture and education zones

55 45 Mixed zones (mixed residential/commercial and industrial zones)

60 50 Industrial concentrated zones and business center zones

65 55 Crossroads and the two sides of roads

70 55

Types of glass and walls

Average acoustic insulation/dB

Types of glass and walls

Average acoustic insulation/dB

Two-layer insulating glass (4+12A+4)①

28 Lateral painted single-layer wall 47-58 (5+6A+5)

25 Double wall with an air layer

51-61 (12+12A+12)

32 Double wall with an air layer and insulating materials

57-62 Three-layer insulating glass (4+12A+4+12A+4)

30-31 Double wall with insulation materials

57-62

4 in ① presents that the glass thickness is 4mm; 12A presents that the spacer layer is a 12mm-thick air layer.

The acoustic insulation of insulating glass is associated with the thickness and the area of the spacer layer, and the greater the thickness and area, the better the acoustic insulation will be. By increasing the thickness and area of the spacer layer, the acoustic insulation of insulating glass will be improved. In addition, the two-layer or multilayer insulating glass composed of the glass and spacer layer of different thickness can effectively improve the acoustic insulation.

Statistics show that a single piece of glass can reduce noise by 20~22dB and two-layer insulating glass by 29~30dB. In order to improve the acoustic insulation of insulating glass, the usually adopted method is to use the glass substrates which are asymmetrical in thickness, fill the spacer layer with dry inert gas or use laminated glass as the substrates to take advantage of the acoustic damping effect of PVB film. By adopting the above method, the acoustic insulation of insulating glass can be up to 45dB.

Dew Prevention of Insulating Glass

The air in insulating glass is dry due to the inside desiccant adsorbing water molecules, and no dew is formed in insulating glass as the temperature decreases, and it can increase the dewpoint of the outer surface. For instance, when the outside wind speed is 5m/s, the indoor temperature 20°C and the relative humidity 60%, dew is formed on 5mm glass when the outdoor temperature is 8 °C, while dew is not formed on 16mm (5+6+5) insulating glass until the outdoor temperature is -2°C under the same conditions, and dew is not formed on 27mm (5+6+5+6+5) three-layer insulating glass until the outdoor temperature is -11°C.

-

Certificates

+ -

Sales network

+Contact:David xu

Mobile:+86 13573200010

Tel:+86 0532-55711426

Fax: +86 0532-86880938

E-mail:sales@qdpioneerglass.com

http://www.qdpioneerglass.com/