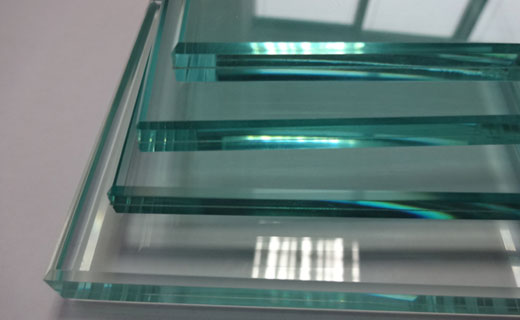

Laminated glass is characterized by transparency, superior mechanical strength, heat resistance, moisture resistance and cold resistance. Compared with common glass, it has superior performance in safety, security, noise insulation and radiation resistance.

1, Extremely high safety and security:With excellent performance in earthquake resistance, shock resistance, penetration resistance, wind pressure resistance and strong PVB adhesion, laminated glass will not result in bodily injury from splashing splinters when it is struck and broken due to external force; it can withstand the attack of burglar's tools, such as hammer and brick. It can improve the penetration resistance by increasing the thickness of the PVB film.

2, Good Acoustic Insulating Performance:PVB film can effectively absorb sound waves and reduce noise pollution;

3, Anti-UV linearity: without loss of visible light at the same time, it can effectively block nearly 99% of the UV into the house and prevent the interior decorations and furniture from fading and aging.

4, Color diversity: according to the needs of customers to produce a variety of colors or patterns of products to meet the engineering design requirements;

5, Thermal Insulating Performance: effectively block the heat transfer, reduce heat transmission, reduce cooling energy consumption;

6, Ballistic performance: through the different thickness of the PVB and the combination of several pieces of glass, it can be made of bullet-proof glass and some high-strength decorative glass or engineering structure glass;

Production Capacity:

Maximum specification: 3600×18000mm;

Minimum specification: 300 × 300mm

PVB film thickness: 0.38mm, 0.76mm, 1.14mm, 1.52mm and 2.28mm;

Total thickness of laminated glass: 2.78~100mm;

Output: 2.5 million m²/year

Orders out of above specifications are negotiable.

Executive Technical and Quality Standards

Complying with European EN12150-2:2004; Australian standard AS/NZS 2208-1996.

Complying with American ANSI Z97.1-2004; Chinese GB15763.2-2005;

1, Comparison of shock resistance parameters is shown as follows:

Table 1-1 Comparison of penetration resistance of laminated glass and other types of glass

Testing Items

|

Annealed glass

|

Tempered glass

|

Laminated glass

|

Glass thickness/mm

|

6

|

6

|

6.38

|

A 2260g steel ball fell freely from 4m high

|

Penetrated

|

Penetrated

|

Not penetrated

|

A 227g steel ball fell freely from 12m high at 40 °C

|

Penetrated

|

Penetrated

|

Not penetrated

|

A 227g steel ball fell freely from 10m high at -20°C

|

Penetrated

|

Penetrated

|

Not penetrated

|

A 10kg human head model fell from 1.5m high

|

Penetrated

|

Penetrated

|

Not penetrated

|

Table 1-2 Penetration resistance of laminated glass with different film

Glass types

|

Status of breakage

|

Laminated glass

|

Security breakage: it might be broken by a pendulum impact, but the glass remained whole, and the pieces and splinters adhered firmly to the interlayer.

|

Annealed glass

|

Broken once get hit, the typical breakage status: bring many elongated sharp splinters

|

Tempered glass

|

Unbroken unless at the huge impact: glass was broken and burst into numerous particles

|

Wired glass

|

Similar with common annealed glass in the status of breakage

|

Coated annealed glass

|

PET film on glass surface can provide additional protection; glass is fragile, and splinters flew toward the inside when the surface film was separated from the broken glass.

|

Table 1-3 Pendulum impact test results of laminated glass and other types of glass

Interlayer film

|

Structure

|

Maximum falling height (MBH)

|

EVA

|

G/0.25mm/G

|

0.70m

|

G/0.40mm/G

|

1.90m

|

G/0.25mm/PET/0.25mm/G

|

3.50m

|

PVB

|

G/0.385mm/G

|

2.75m

|

G/0.76mm/G

|

5.75m

|

2,Thermal Insulating Performance

Table 1-4 Thermal insulation of laminated glass with thermal insulation and energy efficient film

Color

|

clear

|

green

|

blue

|

gray

|

Performance

|

|

|

Visible light transmittance/%

|

82.1

|

71

|

48.2

|

48.8

|

Visible light reflectance/%

|

8.1

|

7.1

|

6.4

|

5.8

|

Solar transmittance/%

|

60.4

|

49.9

|

34.6

|

32.6

|

Solar reflectance/%

|

7.0

|

5.7

|

5.8

|

5.5

|

Solar heat gain coefficient (SHGC)

|

0.69

|

0.61

|

0.50

|

0.49

|

Shading coefficient (SC)

|

0.80

|

0.71

|

0.58

|

0.57

|

3, Acoustic Insulating Performance

Acoustic insulation is another prominent feature of laminated glass in addition to security and thermal insulation. In order to create a comfortable living environment, control of noise has become an important issue in modern architecture.

In general, human auditory system can automatically convert the 10 times acoustic intensity into twice acoustic intensity to create human actual feeling. The loudness of sound audible to the human ear is generally presented in decibels (dB). The sound less than 3dB is inaudible and 5 dB is audible to the human ear, and the maximum tolerable loudness of sound is 130dB. Laminated glass controls noise mainly through absorbing noise and degrading sound energy. Noise reduction is generally measured in weighted sound isolation. Table 1-5 shows the weighted sound isolation of various types of laminated glass.

Table 1-5 Weighted sound isolation of laminated glass

Glass composite/mm

|

3+0.38+3

|

3+0.76+3

|

3+1.14+3

|

5+0.38+5

|

5+0.76+5

|

Weighted sound isolation/dB

|

34

|

35

|

35

|

36

|

36

|

Glass composite/mm

|

6+0.38+6

|

6+0.76+6

|

6+1.14+6

|

6+1.52+6

|

12+1.52+12

|

Weighted sound isolation/dB

|

36

|

38

|

38

|

39

|

41

|

Factors affecting the weighted sound isolation of laminated glass include glass thickness and acoustic damping of the interlayer of laminated glass. Table 1-5 shows that, with the same glass substrate, the weighted sound isolation of laminated glass varies depending on the thickness of the PVB film, and the thicker the PVB film, the better the acoustic insulation.